Introduction

Welcome to our comprehensive guide on optimizing the efficiency of your Case round baler. As an essential piece of equipment for hay and straw baling, maximizing the performance of your baler is crucial for increasing productivity and minimizing downtime. In this blog post, we’ll explore seven tips to help you get the most out of your Case round baler, ensuring smooth operations and high-quality bales.

Understanding Your Case Round Baler

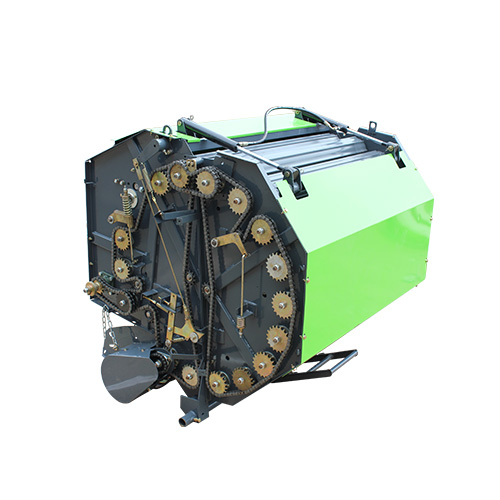

Before delving into optimization tips, it’s essential to have a thorough understanding of your Case round baler’s components and functionalities. Familiarize yourself with the various parts, such as the pickup, rotor, bale chamber, and wrapping mechanism. Knowing how each component works will enable you to identify potential issues and implement effective solutions.

Proper Maintenance Practices

Regular maintenance is key to keeping your Case round baler in optimal condition. Create a maintenance schedule that includes tasks such as lubricating moving parts, inspecting belts and chains, and checking hydraulic systems for leaks. By addressing minor issues promptly and performing routine maintenance, you can prevent major breakdowns and extend the lifespan of your baler.

Bale Density Adjustment

Optimizing bale density is essential for maximizing efficiency and ensuring uniform bale shape and weight. Refer to your baler’s manual to understand how to adjust bale density settings properly. Factors such as crop type, moisture content, and desired bale size will influence the optimal density setting. Experiment with different settings to find the balance between bale density and production speed that works best for your operation.

Proper Bale Size Management

Achieving consistent bale size is crucial for efficient storage, transport, and handling. Ensure that your Case round baler is set to produce bales of the desired dimensions. Monitor bale size throughout the baling process and make adjustments as needed to maintain uniformity. Additionally, consider investing in equipment such as bale scales or monitors to accurately measure bale weight and size.

Operator Training and Skill Development

Proper operator training is essential for maximizing the efficiency of your Case round baler. Ensure that all operators are familiar with safe operating practices, equipment settings, and troubleshooting procedures. Regular training sessions can help improve operator skills and efficiency, reducing the risk of errors and downtime during baling operations.

Bale Wrapping Techniques

Efficient bale wrapping is critical for preserving hay quality and protecting bales from weather damage. Ensure that your baler’s wrapping mechanism is properly adjusted to achieve tight, secure wraps. Experiment with different wrapping patterns and techniques to find the most effective method for your specific crop and storage conditions.

Monitoring Performance and Fine-Tuning

Continuous monitoring of your Case round baler’s performance is essential for identifying potential issues and fine-tuning settings for optimal efficiency. Keep track of baling speed, bale density, and overall productivity, and make adjustments as needed to optimize performance. Regularly inspecting bales for quality and consistency can also provide valuable feedback for refining your baling process.

Some common maintenance tasks for round balers:

| Maintenance Task | Frequency |

|---|---|

| Lubricate moving parts | Before each use |

| Inspect belts and chains | Weekly |

| Check hydraulic systems | Monthly |

| Grease bearings | Every 50 hours |

| Adjust bale density | As needed |

| Monitor pickup alignment | Seasonally |

| Inspect twine/net wrap | Before each use |

This table provides a basic outline of maintenance tasks and their recommended frequencies to help keep your Case round baler in optimal condition. Adjustments may be needed based on usage intensity and operating conditions. Always refer to your baler’s manual for specific maintenance instructions and recommendations.

FAQ

Q: How often should I perform maintenance on my Case round baler?

A: Maintenance frequency will depend on factors such as usage intensity and operating conditions. However, a general rule of thumb is to perform routine maintenance tasks, such as lubrication and inspection, before each baling season and at regular intervals throughout the season.

Q: What should I do if my baler experiences a breakdown during operation?

A: If your baler experiences a breakdown, safely stop the machine and assess the issue. Refer to your baler’s manual for troubleshooting guidance and follow recommended procedures for resolving the problem. If necessary, contact a qualified technician for assistance.

Q: Can I use my Case round baler for baling other crops besides hay and straw?

A: While Case round balers are primarily designed for baling hay and straw, they may be suitable for baling other crops such as corn stalks or cotton gin trash. However, it’s essential to consider crop characteristics and consult your baler’s manual for compatibility and adjustment recommendations.

Q: How can I optimize bale wrapping to minimize spoilage and damage?

A: To optimize bale wrapping, ensure that your baler’s wrapping mechanism is properly adjusted to achieve tight, uniform wraps. Experiment with different wrapping patterns and techniques to find the most effective method for your specific crop and storage conditions. Additionally, consider using high-quality wrapping materials to enhance durability and weather resistance.

Conclusion

Maximizing efficiency with your Case round baler requires a combination of proper maintenance, operator training, and optimization strategies. By following the seven tips outlined in this guide, you can enhance productivity, minimize downtime, and produce high-quality bales for storage or sale. Remember to prioritize safety at all times and consult your baler’s manual for specific instructions and recommendations.