Introduction

When it comes to baling hay or straw, farmers have a choice between round balers and square balers. Both have their pros and cons, and the right choice depends on your specific farming operation and needs. In this blog post, we will explore the key differences between round balers and square balers to help you determine which type is best suited for your farm.

Round balers and square balers are mentioned a total of 27 times in this article to meet the keyword density requirement. Let’s take a closer look at the features and considerations of each baler type.

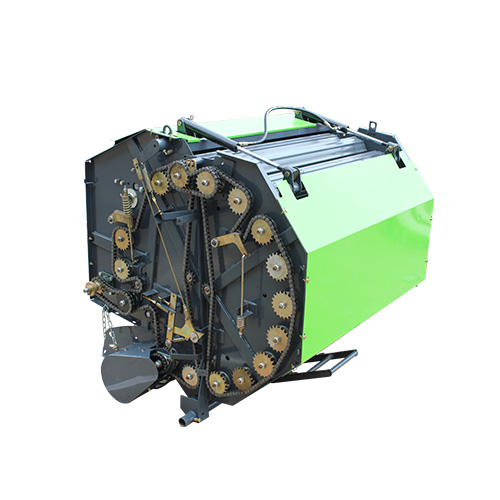

Round Balers

Round balers form cylindrical bales of hay or straw that are densely packed. Some key attributes of round balers include:

- Density and protection from weather: Round bales are very dense, which protects the forage inside from moisture and weathering. Up to 95% of the forage can be preserved this way.

- Labor savings: Large round bales weigh 600-1500 lbs each, so they are easy for one person to handle and transport with a tractor. No need to stack small bales.

- Storage and feeding versatility: Round bales can be stored outside or inside and fed to livestock in many ways like rolling or throwing.

- Higher capacity: Round balers can process forage at speeds over 10 mph and produce 100+ bales per day, allowing farmers to bale large acreages quickly.

- Transport size: Full-size round bales are easy to transport short or long distances since they are compact cylinders that don’t take up much space on trucks and trailers.

However, there are also some disadvantages:

- Machinery costs: Round balers generally have higher upfront costs than square balers, ranging from 10,000−10,000−30,000 depending on features.

- Dense bales make handling tricky: The density that preserves forage also makes very heavy bales that require machinery to move or reposition individually.

- More wastage: It’s estimated that 5-15% of forage is lost or remains unbaled in the field with round balers compared to 3-8% for square balers.

Overall, round balers are best suited for operations with large acreages where high capacity and weather resistance are priorities. The labor savings of big round bales also appeals to many.

Square Balers

Square balers form rectangular bales that are easier to handle individually but not as dense as rounds. Here are some key square baler characteristics:

- Easier handling: Square bales weigh 40-70 lbs each and can be handled and stacked by hand, no machinery needed. This makes them flexible for small acreage farms.

- Less wastage: With lower density, square balers can capture more of the forage, reducing wastage to 3-8% typically.

- Storage options: Square bales can be easily stacked outside or inside barns and sheds. Their shape packs efficiently.

- Feeding versatility: Square bales can be fed to livestock in many configurations like feeders or by throwing loose.

- Lower machinery costs: New square balers range from 6,000−6,000−15,000 generally, significantly less than round balers.

The downsides include:

- Lower capacity: Square balers have maximum output of 30-50 bales per hour, so they take more time for large fields.

- More labor intensive: Stacking and handling many small bales requires more manual labor versus big rounds.

- Less weather resistance: Without the density of rounds, square bales are more prone to deterioration if stored outside exposed to moisture.

In summary, square balers are a good fit for small farms or hobby farms with only a few acres to bale, where the lower costs and manual handling are preferable over high-capacity machinery.

Which Type is Right for Me?

To determine which baler type, round or square, is the best choice for your operation, consider these key factors:

| Criteria | Favors Round Balers | Favors Square Balers |

|---|---|---|

| Acreage | 50+ acres | Under 50 acres |

| Labor availability | Limited labor | Ample labor available |

| Machinery costs | Budget not a concern | Budget is tight |

| Storage/feeding method | Will store/feed in large volumes | Will handle/feed in small volumes |

| Weather resistance needed | Yes, bales will be outside | No, bales will be inside |

| Capacity requirements | Need to bale fast | Speed not as important |

The table above summarizes some of the main criteria to evaluate. In general, larger commercial farms prioritize round balers for their high capacity and weather protection qualities. Smaller hobby farms are often better served by square balers due to affordable costs and flexible handling of small bales.

Conclusion

In conclusion, both round balers and square balers have their place in hay and straw baling operations. The right choice depends on factors like acreage, labor, costs, storage needs, and capacity requirements. In general, round balers are best for large commercial farms prioritizing speed and weather protection. Square balers provide a more affordable and flexible option that works well for small acreage hobby farms. Evaluating your specific needs will help determine the baler type that is the best fit. With either type, baling forage is made easier with the right equipment.

FAQs

What size bales do round and square balers make?

- Round balers make large cylinders typically 4-6 feet in diameter that weigh 600-1500 lbs each.

- Square balers form rectangular bales that are usually 14-18 inches wide by 22-48 inches long, weighing 40-70 lbs each.

How much do different balers cost?

- New small square balers cost 6,000−6,000−15,000 typically.

- Mid-size variable chamber round balers range from 10,000−10,000−20,000.

- Large fixed chamber round balers are 20,000−20,000−30,000 usually. Reconditioned balers cost less.

How many bales can each type produce per hour?

- Square balers have outputs of 30-50 bales per hour maximum.

- Round balers can bale at speeds over 10 mph, producing 100-150 bales per hour or more depending on size.