Introduction

The agricultural industry continuously evolves, with advancements in machinery playing a pivotal role in improving productivity and efficiency. One such piece of equipment that has revolutionized the farming sector is the round bale baler. Designed to compact hay, straw, or other forage crops into cylindrical bales, round bale balers offer numerous benefits that can significantly enhance farm operations. This comprehensive guide delves into the top benefits of using a round bale baler on your farm, exploring its impact on productivity, cost savings, and overall farm management.

The Evolution of Round Bale Balers

Historical Context

Before the advent of round bale balers, farmers relied on manual labor or simple machines to handle forage crops. Traditional methods were labor-intensive, time-consuming, and often resulted in inconsistent bale quality. The introduction of the round bale baler marked a significant leap forward in agricultural technology.

- Manual Labor: Intensive and time-consuming.

- Early Machines: Simple but inefficient.

- Modern Balers: Automated and highly efficient.

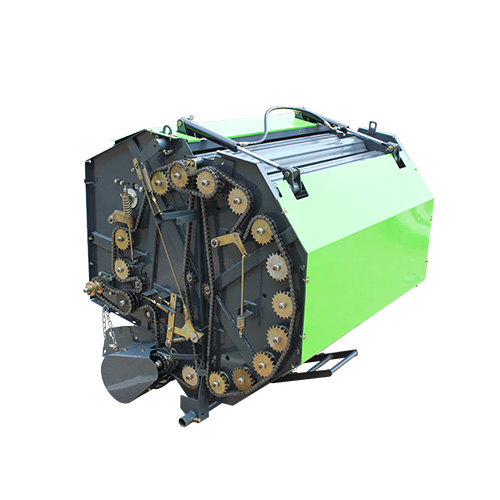

Technological Advancements

Modern round bale balers are equipped with advanced features that enhance their performance and ease of use. These advancements include:

- Automatic Wrapping: Ensures consistent bale protection.

- Moisture Sensors: Optimize baling conditions.

- Variable Chamber Sizes: Allow customization of bale sizes.

Key Benefits of Using a Round Bale Baler

Increased Efficiency and Productivity

One of the most significant benefits of using a round bale baler is the substantial increase in efficiency and productivity on the farm. The automation and advanced features of modern balers allow for quicker and more consistent baling, reducing the time and labor required.

- Faster Baling: High-speed operation reduces time spent in the field.

- Consistent Bale Quality: Uniform bales ensure better storage and handling.

- Labor Savings: Reduces the need for manual labor, allowing workers to focus on other tasks.

Cost Savings

The efficiency of round bale balers translates directly into cost savings. By optimizing the baling process, farmers can reduce operational costs, including labor, fuel, and maintenance expenses.

- Lower Labor Costs: Automation reduces the need for manual labor.

- Fuel Efficiency: Modern balers are designed to use less fuel.

- Reduced Maintenance: Advanced technology minimizes wear and tear.

Improved Forage Quality

Round bale balers are designed to maintain the quality of forage during the baling process. Features such as moisture sensors and automatic wrapping help preserve the nutritional value of the forage, ensuring better feed for livestock.

- Nutrient Preservation: Maintains the nutritional value of forage.

- Reduced Spoilage: Proper wrapping and storage reduce spoilage.

- Better Livestock Feed: High-quality forage leads to healthier livestock.

Enhanced Storage and Handling

The uniform size and shape of round bales make them easier to handle and store. This improved manageability leads to more efficient use of storage space and simplified transportation.

- Efficient Storage: Maximizes storage space.

- Easy Handling: Simplifies loading and unloading.

- Safe Transportation: Uniform bales reduce the risk of accidents during transport.

Versatility and Adaptability

Round bale balers are versatile machines capable of handling various types of forage crops, including hay, straw, and silage. This adaptability makes them suitable for different farming operations and conditions.

- Multiple Crops: Can bale hay, straw, silage, and more.

- Adaptable to Conditions: Performs well in various weather conditions.

- Customizable Bales: Allows for different bale sizes and densities.

Table: Comparison of Round Bale Balers and Square Bale Balers

| Feature | Round Bale Baler | Square Bale Baler |

|---|---|---|

| Bale Shape | Cylindrical | Rectangular |

| Bale Size | Variable | Fixed |

| Efficiency | Higher due to automation | Moderate |

| Storage and Handling | Easier due to uniform size | Requires more manual handling |

| Forage Quality | Better preservation with wrapping | Variable, dependent on conditions |

| Cost | Generally higher initial investment | Lower initial investment |

| Versatility | Handles multiple forage types | Limited to specific forage types |

| Labor Requirement | Lower due to automation | Higher due to manual handling |

| Maintenance | Lower with advanced features | Higher due to mechanical complexity |

| Popularity | Increasing due to benefits | Traditional choice, still widely used |

Practical Applications of Round Bale Balers

Hay Production

In hay production, round bale balers are invaluable for efficiently processing large volumes of hay. The automation and consistent bale quality ensure that the hay retains its nutritional value, providing high-quality feed for livestock.

- Efficiency: Faster processing of hay.

- Quality: Maintains nutritional value.

Straw Baling

Straw baling is another application where round bale balers excel. The ability to create uniform bales simplifies storage and transportation, making straw easier to manage and utilize.

- Uniform Bales: Simplifies storage and handling.

- Versatility: Suitable for different types of straw.

Silage Production

For silage production, round bale balers equipped with wrapping capabilities are particularly beneficial. The wrapping process preserves the silage’s moisture content and nutritional value, ensuring high-quality feed.

- Moisture Preservation: Maintains the ideal moisture level.

- Nutritional Value: Ensures high-quality feed.

Conclusion

The adoption of round bale balers on farms has brought about significant improvements in efficiency, cost savings, forage quality, and ease of storage and handling. Their versatility and adaptability make them an essential tool for modern farming operations. By understanding the benefits and applications of round bale balers, farmers can make informed decisions to enhance their productivity and overall farm management.

FAQ

What are the main benefits of using a round bale baler?

The main benefits of using a round bale baler include increased efficiency and productivity, cost savings, improved forage quality, enhanced storage and handling, and versatility in handling various types of forage crops.

How does a round bale baler improve forage quality?

Round bale balers improve forage quality by using features such as moisture sensors and automatic wrapping to preserve the nutritional value of the forage. This ensures that the feed remains high-quality and reduces spoilage.

Are round bale balers suitable for all types of forage crops?

Yes, round bale balers are versatile and can handle various types of forage crops, including hay, straw, and silage. Their adaptability makes them suitable for different farming operations and conditions.

What are the cost implications of using a round bale baler?

While the initial investment for a round bale baler may be higher, the cost savings in terms of reduced labor, fuel efficiency, and lower maintenance expenses can offset the initial cost. The increased productivity and forage quality also contribute to overall cost-effectiveness.

How do round balers enhance storage and handling?

Round balers create uniform cylindrical bales that are easier to handle and store. This improved manageability leads to more efficient use of storage space, simplified transportation, and reduced risk of accidents during handling.

Can round balers be used in different weather conditions?

Yes, round balers are designed to perform well in various weather conditions. Features like moisture sensors help optimize baling conditions, ensuring consistent performance regardless of the weather.

What maintenance is required for a round baler?

Round balers require regular maintenance to ensure optimal performance. This includes checking and adjusting the belts, cleaning the machine, lubricating moving parts, and inspecting the wrapping mechanism. Advanced balers with fewer mechanical parts may require less maintenance.

How do round balers compare to square bale balers?

Round balers offer higher efficiency, better forage preservation, and easier handling and storage compared to square balers. However, square bale balers may have a lower initial investment cost and are still widely used in certain applications.

What should I consider when choosing a round baler?

When choosing a round baler, consider factors such as the types of forage crops you handle, the size and density of the bales you need, the baler’s advanced features, and your budget. Assessing these factors will help you select the right baler for your farm’s specific needs.

Are round balers environmentally friendly?

Round balers can be environmentally friendly as they help reduce forage spoilage, ensuring that less waste is generated. Additionally, modern balers are designed for fuel efficiency, reducing their environmental impact. Proper maintenance and use of the baler can further enhance its eco-friendliness.